Conveyor System Automation refers to the integration of automated controls, sensors, and drive systems into conveyors to enable efficient, continuous, and safe material handling. At Harsha Engineers India, we provide customized automated conveyor solutions that streamline production, reduce labor costs, and improve efficiency across diverse industries. Our systems handle bulk materials, packaged goods, and heavy loads with precision and reliability.

Automated Control Systems – PLC, SCADA, and HMI-based conveyor monitoring.

Smart Sensors – For load detection, speed control, and fault monitoring.

Custom Conveyor Types – Belt, roller, screw, chain, slat, and overhead conveyors.

Variable Speed Drives (VFDs) – Adjustable speed for optimized material flow.

Integration Capability – Compatible with robotics, packaging machines, and ERP systems.

Energy Efficient – Designed to minimize power consumption.

Safety Systems – Emergency stops, interlocks, and safety guards.

Manufacturing Plants – Movement of raw materials, semi-finished, and finished goods.

Pharmaceutical Industry – Automated handling of sterile and packaged medicines.

Food & Beverage Industry – Hygienic transport of packaged foods and beverages.

Mining & Construction – Handling aggregates, ores, and bulk materials.

Warehousing & Logistics – Automated sorting, packing, and dispatch systems.

Automotive Industry – Assembly line conveyors for parts and vehicle components.

Chemical Industry – Safe transfer of chemicals and packaged products.

(Customizable as per project needs)

Conveyor Types: Belt, roller, chain, screw, slat, modular, overhead

Load Capacity: From a few kilograms to several tons

Conveyor Lengths: 1 meter to 100+ meters (customizable)

Speed Range: 0.1 m/s to 5 m/s with VFD control

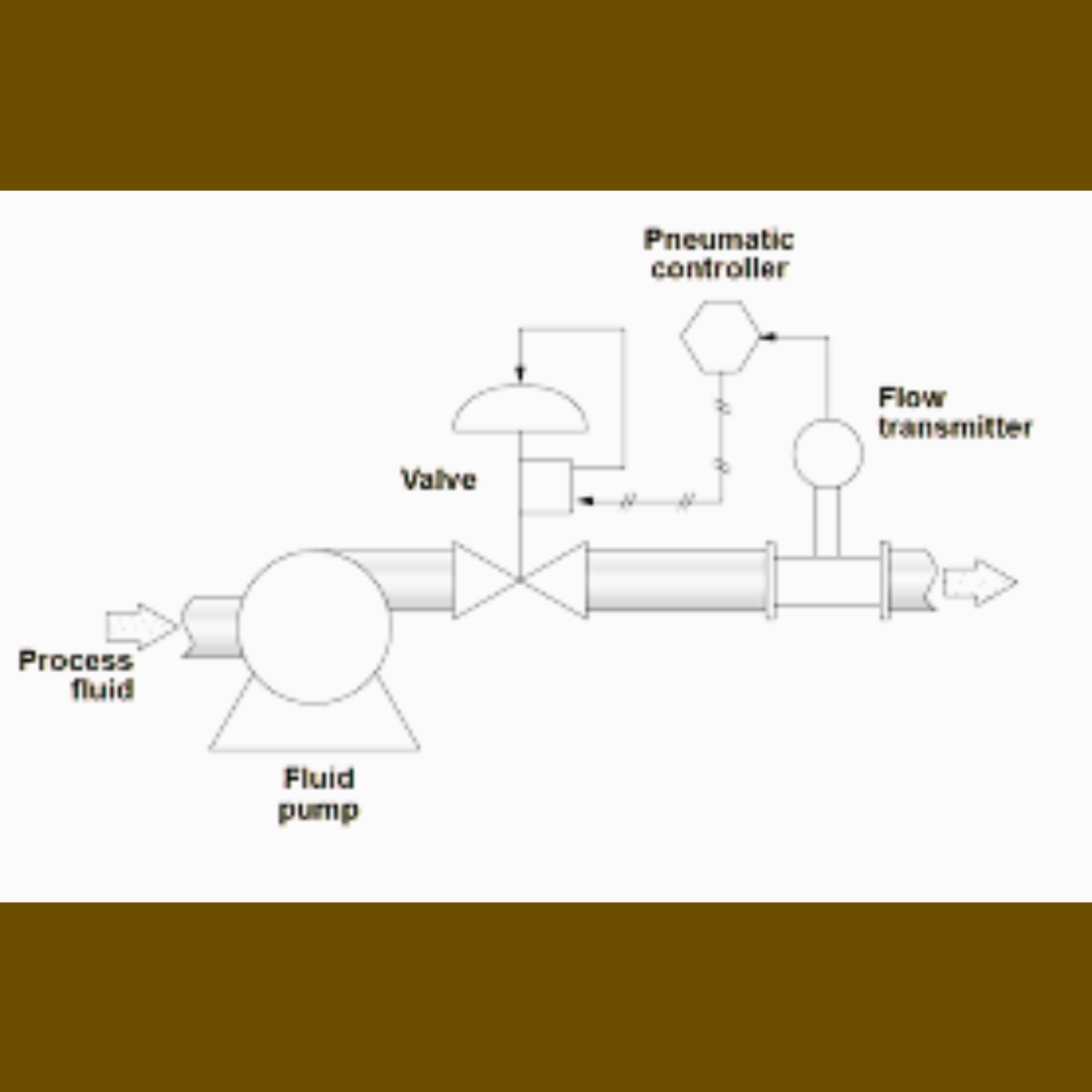

Drive Systems: Electric motors, hydraulic drives, pneumatic systems

Automation Control: PLC, SCADA, IoT-enabled systems

Safety Features: Emergency stops, overload protection, safety sensors

Increased Productivity – Continuous material movement boosts efficiency.

Reduced Labor Costs – Minimizes manual handling and dependency.

Improved Safety – Reduces workplace injuries with automated handling.

Customizable – Can be tailored for specific industry applications.

Consistent Quality – Smooth handling reduces damage and errors.

Scalable Solutions – Expandable to meet future production growth.

Automated control of reactors, mixers, separators Pressure, temperature, and pH monitoring & control Batch & continuous process automation

Complete plant automation using PLC/DCS systems. SCADA integration for real-time monitoring Safety interlock systems (SIS). Energy optimization and plant-wide efficiency control.

Smart flowmeters (mass, magnetic, ultrasonic). Automated valves, pumps & dosing systems. Closed-loop monitoring for accuracy and efficiency.

Bottle, drum, and bag filling automation. Automated weighing, sealing & labeling. High-speed packaging lines with minimum manpower.

PLC, MCC & VFD-based panels. HMI & SCADA integration cabinets. Remote monitoring & control panels. Customized panel design & fabrication.

Barcode & RFID tracking solutions. Automated scanning with vision systems. Real-time data processing & ERP/MES integration. Online production monitoring dashboards.

Copyright Reserved © Harsha Engineers

Powered by Rashmita Infinity – Hyderabad (Digital Marketing agency in Hyderabad)