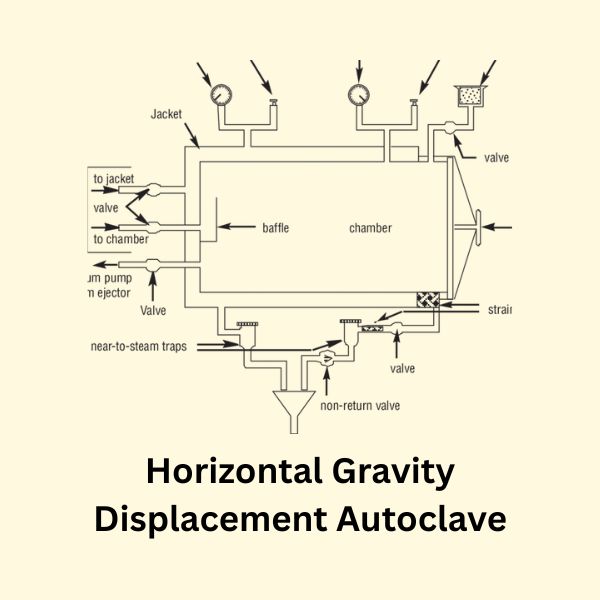

At Harsha Engineers, we manufacture Horizontal Gravity Displacement Autoclaves designed for large-scale sterilization needs in hospitals, pharmaceutical industries, research laboratories, and industrial applications. These autoclaves operate on the principle of gravity displacement, where steam enters the chamber, forcing out the air through a drain to ensure uniform and effective sterilization. Built with robust construction and precision engineering, our horizontal autoclaves are ideal for handling bulk loads such as surgical instruments, hospital linens, culture media, glassware, and laboratory equipment.

Engineered for efficiency and reliability, our horizontal autoclaves feature user-friendly controls, excellent safety mechanisms, and durable materials of construction to ensure long service life. Their large chamber capacity, consistent sterilization performance, and compliance with international quality standards make them a trusted choice for institutions that demand high-capacity and dependable sterilization equipment. With Harsha Engineers’ expertise, clients can rely on advanced solutions that combine quality, safety, and performance.

Design Type: Horizontal cylindrical, double-walled (inner chamber & outer jacket)

Material of Construction (MOC): Stainless Steel SS304 / SS316 (chamber & door)

Chamber Volume: 50 liters to 2000 liters (customizable)

Operating Pressure: 15 psi to 30 psi (1.0 to 2.1 kg/cm²)

Operating Temperature: 121°C to 134°C (programmable)

Heating System: Electric heaters / steam heated (as per requirement)

Door Type: Radial locking / sliding door with safety interlocks

Control System: Semi-automatic / PLC-based with digital temperature & pressure display

Safety Features:

Pressure safety valve

Low water level cutoff

Automatic pressure control

Door safety lock (prevents opening under pressure)

Mounting: Floor-mounted, insulated body with castor wheels (optional for mobility)

Utilities Required: Electricity, water supply, and drainage

The Horizontal Gravity Displacement Autoclave operates on the principle of gravity displacement, where steam is introduced into the sterilization chamber and displaces the heavier air downwards and out through a vent or drain. Once the air is removed, saturated steam fills the chamber and comes in direct contact with the load, ensuring thorough sterilization. This method is highly effective for sterilizing large volumes of instruments, dressings, and laboratory materials in bulk, making it ideal for hospitals, research centers

Hospitals & Healthcare – Sterilization of surgical instruments, dressings, linen, and medical tools

Pharmaceuticals – Sterilization of glassware, equipment, and culture media

Research Laboratories – Sterilization of laboratory instruments and samples

Food & Beverage Industry – Sterilization of containers, utensils, and raw material testing samples

Biotechnology – Sterilization of culture media, bioreactor accessories, and lab consumables

Efficient sterilization using saturated steam under controlled pressure

Uniform steam penetration due to gravity displacement principle

Large capacity design suitable for bulk sterilization

Sturdy SS construction ensuring durability and long life

Fully customizable chamber sizes to meet specific requirements

Safety interlocks for operator protection

Easy maintenance and long-term operational reliability

The Horizontal Gravity Displacement Autoclave is a cost-effective and reliable sterilization system for industries and institutions that require safe, efficient, and large-scale sterilization. With robust design, advanced safety features, and customizable options, it plays a vital role in ensuring contamination-free processes across multiple industries.

Copyright Reserved © Harsha Engineers

Powered by Rashmita Infinity – Hyderabad (Digital Marketing agency in Hyderabad)