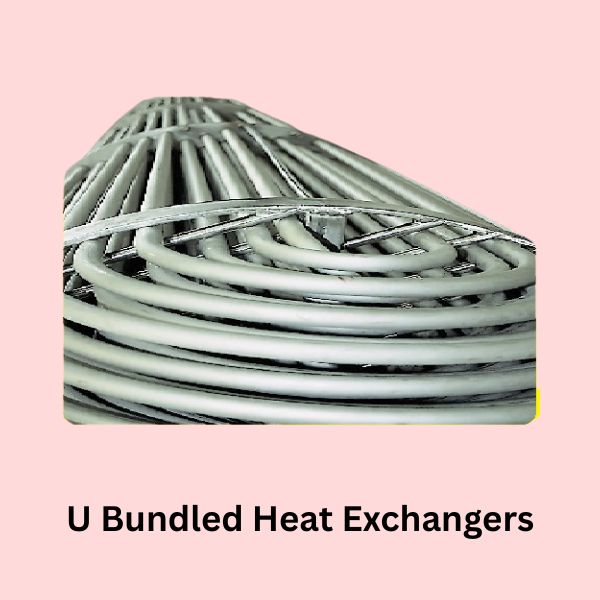

At Harsha Engineers, we specialize in manufacturing durable and efficient U-Bundled Heat Exchangers, designed for applications requiring high thermal efficiency and ease of maintenance. In this design, the tubes are bent into a U-shape, allowing the exchanger to accommodate thermal expansion without requiring additional joints or expansion fittings.

U-bundle heat exchangers are widely used in chemical industries, oil refineries, petrochemicals, pharmaceuticals, and power plants for heating, cooling, and condensing fluids. Their compact design ensures efficient heat transfer while reducing space requirements.

Built from stainless steel, mild steel, or special alloys, our exchangers are engineered to perform reliably under high pressure and temperature conditions. With a focus on quality, safety, and long service life, Harsha Engineers delivers solutions that optimize process efficiency and minimize downtime.

Material of Construction (MOC): MS, SS 304, SS 316, Duplex Steel, Titanium, Hastelloy.

Tube Diameter: 6 mm to 38 mm.

Tube Length: Up to 6 meters (custom-built).

Shell Diameter: 100 mm to 2000 mm.

Design Pressure: Up to 60 bar.

Design Temperature: -50°C to +500°C.

Pass Arrangement: Single-pass or multi-pass options.

Standards: ASME, TEMA, or GMP-compliant.

In a U-Bundled Heat Exchanger, one fluid flows inside the U-shaped tubes, while the other fluid flows around the tubes within the shell.

The U-tube design allows the tube bundle to absorb thermal expansion without causing stress on the joints.

This design also makes it easier to handle high-temperature and high-pressure fluids.

Heat is transferred between the two fluids through the tube walls, ensuring efficient heating or cooling.

U-Bundled Heat Exchangers are widely used where thermal expansion and high temperature differences are major concerns:

Chemical Industry: Cooling, heating, and condensation of chemical fluids.

Petrochemical & Refineries: Crude oil heating, steam services, and hydrocarbon processing.

Power Plants: Boiler feedwater heating, turbine lube oil cooling, steam condensation.

Pharmaceuticals: Process fluid heating and cooling.

Food & Beverage Industry: Heating/cooling of milk, juice, and other liquids.

Marine & Offshore Applications: Seawater cooling and oil heat recovery.

Handles high thermal expansion without stress-related failures.

Robust and durable design for high-pressure and high-temperature applications.

Compact construction with efficient space utilization.

Easy maintenance as the tube bundle can be removed for cleaning.

Versatile material options suitable for corrosive or high-temperature fluids.

Reliable performance with long service life.

U-Bundled Heat Exchangers from Harsha Engineers are engineered to provide efficient, durable, and safe heat transfer solutions for demanding applications. Their flexible tube design, high resistance to thermal stress, and easy maintenance make them the preferred choice in industries such as chemical, petrochemical, power generation, and food processing. With our expertise, we deliver custom-designed U-Tube Heat Exchangers that meet international quality standards and ensure optimum thermal efficiency and reliability.

Copyright Reserved © Harsha Engineers

Powered by Rashmita Infinity – Hyderabad (Digital Marketing agency in Hyderabad)