An autoclave is a specialized pressure vessel designed to carry out sterilization and other chemical processes requiring elevated temperature and pressure. It operates by using steam at high pressure to kill microorganisms, remove contaminants, and ensure complete sterilization of equipment, raw materials, or finished products. Autoclaves are widely used in pharmaceutical, chemical, food processing, healthcare, and research laboratories for sterilizing instruments, glassware, media, and even large-scale industrial components.

They come in different sizes and types—such as vertical, horizontal, portable, and industrial-grade—depending on the application. With safety features like pressure controls, locking systems, and temperature monitoring, autoclaves guarantee reliable, consistent, and contamination-free results. Beyond sterilization, they are also used in curing composites, vulcanizing rubber, and processing materials that require controlled heat and pressure.

Material of Construction (MOC): MS, SS 304, SS 316, Duplex Steel, Hastelloy, Titanium.

Tube Diameter: 6 mm to 50 mm.

Tube Lengths: Up to 6 meters (customized).

Shell Diameter: 100 mm to 2000 mm.

Design Pressure: Up to 50 bar or as required.

Design Temperature: -50°C to +400°C.

Flow Arrangement: Counter-flow, Parallel-flow, or Cross-flow.

Standards: ASME, TEMA, GMP-compliant designs available.

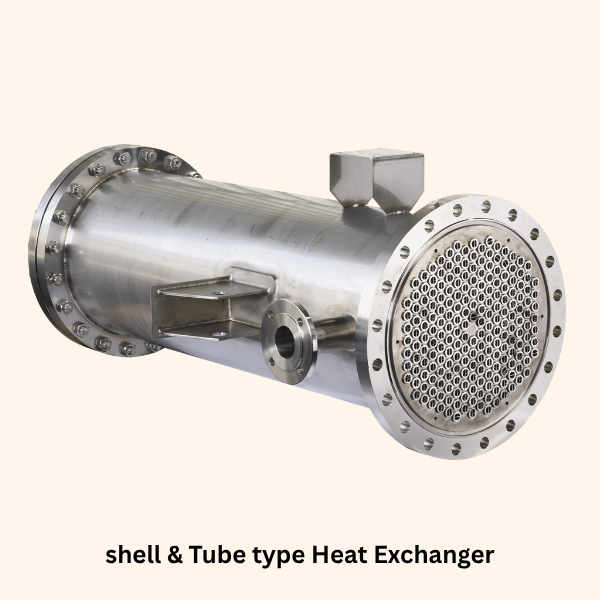

One fluid flows through the tube side, while another fluid flows over the shell side.

Heat is transferred across the tube walls, allowing one fluid to be heated while the other is cooled.

The arrangement can be counter-flow, parallel-flow, or cross-flow, depending on the thermal efficiency required.

Baffles are often used inside the shell to direct the fluid, improve turbulence, and enhance heat transfer.

Shell & Tube Heat Exchangers are used in industries that require reliable thermal management:

Pharmaceutical & Chemical Industries: Cooling, heating, and condensation of solvents, acids, and process fluids.

Petrochemical & Oil Refineries: Heat recovery, crude oil heating, and cooling of process streams.

Power Plants: Steam condensation, boiler feedwater heating.

Food & Beverage Industry: Pasteurization, juice cooling, sugar processing.

HVAC & Refrigeration: Chillers, condensers, and evaporators.

Marine & Offshore Applications: Seawater cooling, lube oil cooling.

High heat transfer efficiency with compact design.

Handles high pressure and temperature ranges.

Suitable for a wide variety of fluids including corrosive media.

Easy maintenance and cleaning due to tube bundle removal.

Flexible design options (U-tube, fixed tube sheet, floating head).

Long service life with durable construction.

Customizable for specific process requirements.

Shell & Tube Heat Exchangers from Harsha Engineers are engineered for maximum thermal efficiency, durability, and reliability. With our expertise in customized designs, quality fabrication, and GMP compliance, we deliver heat exchangers that meet the stringent demands of pharmaceutical, chemical, petrochemical, and energy sectors. Our solutions ensure optimum energy utilization, reduced operational costs, and long-lasting performance.

Copyright Reserved © Harsha Engineers

Powered by Rashmita Infinity – Hyderabad (Digital Marketing agency in Hyderabad)