A Gravity Displacement Autoclave is a reliable sterilization system that uses steam to displace the air inside the chamber through gravity. It is simple to operate and highly effective for sterilizing laboratory instruments, glassware, medical tools, and culture media.

In this method, steam enters the chamber and pushes the air out through a vent, allowing saturated steam to contact every surface for complete sterilization. Gravity autoclaves are widely used in hospitals, research laboratories, and small-scale industrial applications due to their ease of use, cost-effectiveness, and consistent performance.

Built with durable stainless steel and equipped with safety features like pressure controls and locking mechanisms, our gravity displacement autoclaves ensure safe, efficient, and contamination-free sterilization.

Design Type: Vertical, Horizontal, Tabletop, or Portable models

Chamber Material: Stainless Steel (SS 304 / SS 316 as per requirement)

Outer Body: Stainless Steel / Mild Steel with epoxy coating

Chamber Capacity: 10 liters to 500 liters (customized as per client needs)

Sterilization Temperature Range: 121°C to 134°C

Operating Pressure: 15 – 20 psi (1.05 – 1.4 kg/cm²)

Heating System: Electrically heated / steam heated options available

Door Type: Radial lock / hinged door with safety interlock system

Gasket Material: Silicon / Neoprene heat-resistant gasket

Control System: Digital temperature controller with timer, pressure gauge, and safety valve

Power Supply: 220V / 415V AC, single-phase or three-phase, 50 Hz

Safety Features: Pressure relief valve, low-water level cut-off, and safety interlocks

Mounting: Floor mounted / benchtop as per model

Standards Compliance: Designed and tested as per ASME / GMP / ISO standards

For basic laboratory and hospital use, the Gravity Displacement Autoclave is a cost-effective and dependable method of sterilization. For routine applications, liquids, glassware, and solid instruments, it remains an essential and widely used sterilizer, despite its inability to match the efficiency of pre-vacuum or steam-flush models for complex loads.

At Harsha Engineers, we design and supply Portable Gravity Displacement Autoclaves that deliver reliable sterilization in a compact and mobile form. These units work on the principle of gravity displacement, where steam efficiently replaces the air inside the chamber to achieve uniform sterilization. With their lightweight and durable construction, our portable autoclaves are ideal for healthcare centers, laboratories, field operations, and mobile medical services that require quick and dependable sterilization solutions.

Our portable autoclaves are engineered to ensure safety, efficiency, and ease of use. They are particularly suitable for sterilizing surgical instruments, laboratory glassware, and small medical tools in environments where space and resources are limited. Backed by our precision engineering and quality standards, these units are trusted for their performance and adaptability, making them a valuable asset in diverse industries.

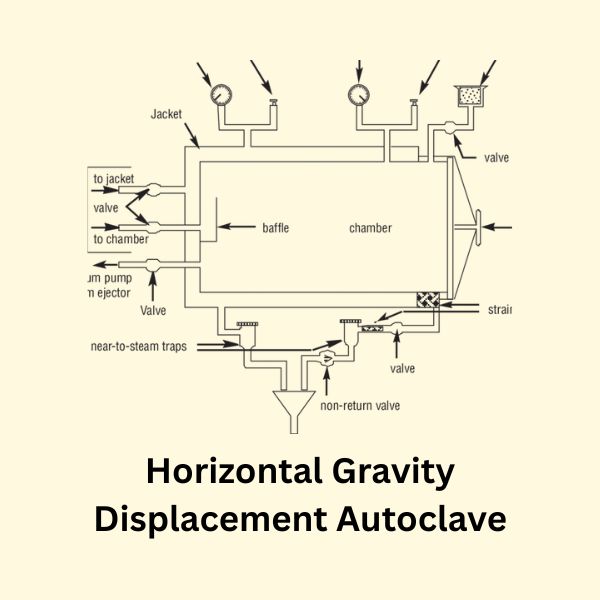

At Harsha Engineers, we manufacture Horizontal Gravity Displacement Autoclaves designed for large-scale sterilization needs in hospitals, pharmaceutical industries, research laboratories, and industrial applications. These autoclaves operate on the principle of gravity displacement, where steam enters the chamber, forcing out the air through a drain to ensure uniform and effective sterilization. Built with robust construction and precision engineering, our horizontal autoclaves are ideal for handling bulk loads such as surgical instruments, hospital linens, culture media, glassware, and laboratory equipment.

Engineered for efficiency and reliability, our horizontal autoclaves feature user-friendly controls, excellent safety mechanisms, and durable materials of construction to ensure long service life. Their large chamber capacity, consistent sterilization performance, and compliance with international quality standards make them a trusted choice for institutions that demand high-capacity and dependable sterilization equipment. With Harsha Engineers’ expertise, clients can rely on advanced solutions that combine quality, safety, and performance.

At Harsha Engineers, we manufacture high-quality Vertical Gravity Displacement Autoclaves designed for efficient sterilization in laboratories, hospitals, and research facilities. Built with a vertical cylindrical chamber, these autoclaves save floor space while ensuring uniform sterilization. They operate on the principle of gravity displacement, where steam replaces the air inside the chamber, providing a safe and reliable sterilization process for laboratory glassware, culture media, dressings, and surgical instruments.

Our vertical autoclaves are engineered with precision to meet industrial and medical standards, ensuring durability and consistent performance. They are available in a wide range of capacities and can be customized with stainless steel construction, safety features, and user-friendly controls. With their robust design, cost-effectiveness, and easy operation, Harsha Engineers Vertical Gravity Displacement Autoclaves are trusted solutions for industries that demand reliable and long-lasting sterilization equipment.

Copyright Reserved © Harsha Engineers

Powered by Rashmita Infinity – Hyderabad (Digital Marketing agency in Hyderabad)